A Comprehensive Guide to Boat Dock Lines

- 1. A Comprehensive Guide to Boat Dock Lines

- 1.1. Types of Boat Dock Lines

- 1.1.1. Twisted Nylon Lines

- 1.1.2. Braided Nylon Lines

- 1.1.3. Polypropylene Lines

- 1.1.4. Double-Braided Lines

- 1.2. Considerations When Choosing A Boat Dock Line

- 1.2.1. Material Matters

- 1.2.2. Diameter and Strength

- 1.2.3. Length Matters

- 1.2.4. Construction Quality

- 1.2.5. Color Considerations

- 1.2.6. Resistance to UV and Abrasion

- 1.2.7. Floatation Features

- 1.2.8. Number of Lines

- 1.3. Proper Dock Line Usage

- 1.3.1. Setting Up Lines Correctly

- 1.3.2. Maintaining the Right Tension

- 1.3.3. Using Spring Lines

- 1.4. Conclusion

- 1.1. Types of Boat Dock Lines

Dock lines for boats, alternatively referred to as mooring lines or dock ropes, are pivotal for guaranteeing the safety and stability of boats during their mooring at a dock. These lines serve a vital function in averting drift and safeguarding both the boat and the dock against potential harm induced by waves, currents, and wind. This extensive guide delves into various categories of boat dock lines, outlining their essential features, appropriate usage, and tips for maintenance.

Types of Boat Dock Lines

Twisted Nylon Lines

One of the most widely used materials for dock lines is twisted nylon. This type of line is favored for its exceptional strength and elasticity. The twisted construction allows the nylon lines to absorb shock loads effectively, making them suitable for various weather conditions. This elasticity is particularly advantageous in preventing sudden jolts to both the boat and the dock, reducing the risk of damage.

Braided Nylon Lines

Braided nylon lines are an alternative to twisted nylon, offering greater flexibility. The braided construction enhances flexibility, making these lines easier to handle. They are also less prone to unraveling and can be conveniently coiled and stored on board. Boaters often appreciate the ease of use that braided nylon lines provide, especially in situations where quick and efficient handling is essential.

Polypropylene Lines

For those seeking a lightweight and cost-effective option, polypropylene lines are a popular choice. These lines float on water, making them easy to spot and retrieve. Additionally, polypropylene is resistant to rot and mildew, ensuring durability over time. While these lines are less stretchy compared to nylon, they are well-suited for light to moderate loads, offering a balance between performance and affordability.

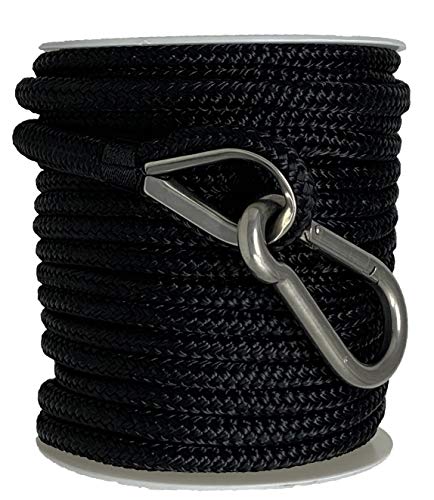

Double-Braided Lines

Double-braided lines are designed with a braided core within a braided cover, resulting in a robust and durable construction. This type of dock line provides excellent strength and is particularly well-suited for larger vessels and heavy-duty applications. The double-braided design enhances both tensile strength and resistance to abrasion, making these lines reliable for extended use in challenging conditions.

Considerations When Choosing A Boat Dock Line

Selecting the appropriate dock lines for your boat is a vital factor in guaranteeing a safe and secure mooring experience. These lines act as the primary link between your boat and the dock, shielding your vessel from the impacts of wind, waves, and shifting tides. When choosing the right dock lines for your boat, here are some essential factors to bear in mind:

Material Matters

- Nylon: Nylon is a popular and versatile choice for dock lines. Its elasticity makes it an excellent shock absorber, effectively handling the impact of waves and wind. Nylon lines offer good strength and durability, and they are resistant to UV rays, providing long-lasting performance.

- Polyester: Another common material for dock lines is polyester. Known for its low stretch, excellent strength, and resistance to UV rays and abrasion, polyester lines are a reliable choice. They are also less prone to degradation from exposure to sunlight compared to nylon.

- Polypropylene: Polypropylene is lightweight, floats on water, and is resistant to rot and mildew. However, it has less stretch compared to nylon, making it less suitable for applications where shock absorption is crucial. Polypropylene is a great choice for lightweight boats and temporary docking.

Diameter and Strength

Choose the diameter and strength of the dock line based on the size and weight of your boat. Larger and heavier boats will require thicker and stronger lines. Refer to the manufacturer's guidelines or consult with a boating expert to determine the appropriate specifications for your vessel.

Length Matters

Ensure that the dock lines are long enough to accommodate changes in water level, tide, and other environmental factors. A longer line not only provides flexibility in tying up your boat but also ensures a secure mooring in various docking scenarios.

Construction Quality

Look for dock lines with professional splicing, featuring eye loops at both ends. Spliced ends are stronger and more reliable than knots, reducing the risk of failure. Invest in lines with quality construction to enhance the overall safety and reliability of your mooring setup.

Color Considerations

While not a critical factor, choosing a highly visible color can make it easier to see and manage your lines, especially in low light conditions or crowded marinas. A bright and easily distinguishable color adds an extra layer of safety to your docking procedures.

Resistance to UV and Abrasion

Continuous exposure to sunlight and contact with abrasive surfaces can degrade the quality of dock lines over time. Ensure that the lines you choose have UV-resistant coatings and are designed to withstand abrasion, ensuring a longer lifespan and reliable performance.

Floatation Features

If your boat dock line might spend extended periods in the water, consider lines that float. Floating lines are easier to retrieve and less likely to get entangled in propellers or submerged obstacles, enhancing the overall safety of your mooring setup.

Number of Lines

Depending on your boat size and the docking setup, you may need different types of lines for various purposes, such as bow lines, stern lines, and spring lines. Ensure you have an adequate number of lines to secure your boat effectively, preventing unnecessary stress on any single line and ensuring a stable mooring configuration.

Proper Dock Line Usage

Setting Up Lines Correctly

- Attach dock lines to both the bow and stern of the boat to prevent it from moving forward or backward.

- Position fenders between the boat and the dock to avoid damage.

Maintaining the Right Tension

- Adjust the tension of the lines to accommodate changes in water level, tide, and weather conditions.

- Lines that are too loose may allow the boat to collide with the dock, while overly tight lines can cause unnecessary strain.

Using Spring Lines

- Spring lines run diagonally from the boat to the dock, preventing lateral movement.

- They are crucial for stabilizing the boat and reducing the risk of collision with neighboring vessels.

Conclusion

Boat dock lines play a crucial role for every boat owner, acting as the primary defense against the unpredictable forces of nature. To guarantee the safety and durability of both vessels and docking infrastructure, it is essential for boat owners to familiarize themselves with the various types of lines, select appropriate sizes, and implement correct usage and maintenance practices. Just like any other boating equipment, staying well-informed and adopting a proactive approach to maintenance will enhance the overall safety and enjoyment of the boating experience.