How to Choose the Bar Clamps

This guide will provide you with all the necessary information to help you choose the right bar clamp for your project.

- 1. Overview of Bar clamps

- 1.1. What are Bar clamps?

- 1.2. Features and components of bar clamps

- 1.2.1. Bar

- 1.2.2. Sliding Jaw

- 1.2.3. Tightening Mechanism

- 1.2.4. Throat Depth

- 1.2.5. Capacity

- 2. Types of Bar Clamps

- 2.1. F-Style Bar Clamps

- 2.2. Parallel Jaw Clamps

- 2.3. One-Handed Bar Clamps

- 2.4. Pipe Clamps

- 2.5. Quick-Grip Bar Clamps

- 2.6. Deep Throat Bar Clamps

- 2.7. Panel Clamps

- 2.8. Corner Clamps

- 2.9. Edge Clamps

- 3. What are purpose of Bar Clamps?

- 3.1. Gluing and Assembly

- 3.2. Joinery and Alignment

- 3.3. Panel and Tabletop Assembly

- 3.4. Bending and Shaping

- 3.5. Machining and Sanding

- 3.6. Holding and Fixturing

- 3.7. Repairs and Restorations

- 3.8. Custom Jigs and Fixtures

- 3.9. Fine Woodworking and Finishing

- 3.10. Temporary Holding

- 3.11. Metalworking and Other Applications

- 4. Benefits of Bar Clamps

- 4.1. Even Pressure Distribution

- 4.2. Versatility

- 4.3. Adjustability

- 4.4. Long Clamping Reach

- 4.5. Parallel Clamping

- 4.6. Durability

- 4.7. Quick and Easy Operation

- 4.8. Accurate Joinery

- 4.9. Custom Jigs and Fixtures

- 4.10. Cost-Effectiveness

- 4.11. Repair and Restoration

- 4.12. DIY and Home Improvement

- 5. How to choose Bar Clamps?

- 5.1. Type of Projects

- 5.2. Clamping Capacity

- 5.3. Throat Depth

- 5.4. Number of Clamps

- 5.5. Quality and Material

- 5.6. Parallel Jaws

- 5.7. Quick Adjustment Mechanism

- 5.8. Bar Length

- 5.9. Grip and Padding

- 5.10. Cost and Budget

- 5.11. User Comfort

- 5.12. Reviews and Recommendations

- 5.13. Brand Reputation

- 5.14. Warranty and Customer Support

- 5.15. Accessories and Compatibility

- 6. In conclusion

Overview of Bar clamps

What are Bar clamps?

Bar clamps are a type of woodworking clamp commonly used to hold pieces of wood together securely during various woodworking tasks. They are designed to apply pressure along the length of a workpiece, ensuring a tight bond between the pieces being glued, screwed, or assembled. Bar clamps consist of a long metal or aluminum bar, a sliding jaw mechanism, and a tightening mechanism.

Features and components of bar clamps

Key features and components of bar clamps include:

Bar

The long, rigid bar is the main component of the clamp. It provides stability and strength while distributing pressure evenly along the length of the workpiece. The bar is usually made of steel or aluminum and may have a T-track or channel along its length to accommodate the sliding jaw.

Sliding Jaw

This movable component runs along the length of the bar and is adjustable to different positions. The sliding jaw is the part of the clamp that makes direct contact with the workpieces. It typically has rubber or non-marring pads to protect the work surface and provide grip.

Tightening Mechanism

Bar clamps feature a mechanism to tighten the sliding jaw against the workpieces, applying pressure and holding them together securely. This mechanism could be a threaded rod with a handle or a lever, allowing the user to easily adjust and control the clamping force.

Throat Depth

The distance between the bar and the sliding jaw is known as the throat depth. This dimension determines how far from the edge of the workpiece the clamp can exert pressure. Bar clamps with greater throat depth can handle larger workpieces or assemblies.

Capacity

The maximum opening width of the bar clamp indicates the size of workpieces it can accommodate. Different sizes of bar clamps are available to suit various project requirements.

Bar clamps are versatile and can be used for a wide range of woodworking applications, such as gluing, edge joining, panel assembly, and holding components in place during machining or finishing processes. They are popular due to their strong, even pressure distribution and ease of use.

When using bar clamps, it's important to ensure that the sliding jaw is parallel to the workpiece and that the pressure is evenly distributed to avoid warping or damaging the wood. Proper clamping techniques and tools contribute to successful woodworking projects.

Types of Bar Clamps

There are several types of bar clamps available, each designed to suit specific woodworking needs and preferences. Some of the common types of bar clamps include:

F-Style Bar Clamps

These are the most traditional and widely used bar clamps. They have an "F" shape, with a fixed jaw and a sliding jaw that moves along a bar. The sliding jaw is adjusted using a threaded rod and handle. F-style bar clamps come in various sizes and are suitable for a wide range of woodworking tasks.

Parallel Jaw Clamps

Parallel jaw clamps, also known as parallel clamps, have jaws that remain parallel to each other throughout their range of motion. This feature helps maintain even pressure and prevents the workpieces from being skewed or misaligned during clamping. Parallel jaw clamps are particularly useful for gluing and assembling large panels, doors, and other projects that require precise alignment.

One-Handed Bar Clamps

One-handed bar clamps are designed for ease of use and convenience. They typically have a trigger mechanism that allows you to quickly adjust and release the clamping pressure with one hand. These clamps are ideal for tasks where you need to hold the workpiece in place and tighten the clamp simultaneously.

Pipe Clamps

Pipe clamps use sections of threaded pipe as the bar component. They are versatile and can be customized to various lengths by adding or removing pipe sections. Pipe clamps are often used for larger projects and can be a cost-effective solution for long clamping spans.

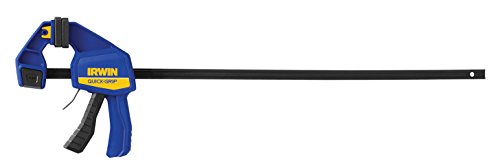

Quick-Grip Bar Clamps

Quick-grip bar clamps feature a pistol grip handle that allows for rapid clamping and release. These clamps are designed for quick adjustments and are suitable for light-duty clamping tasks.

Deep Throat Bar Clamps

Deep throat bar clamps have an extended throat depth, which means they can reach further into a workpiece to apply pressure. This type of clamp is useful for clamping workpieces with larger dimensions or for reaching areas that are difficult to access.

Panel Clamps

Panel clamps are specifically designed for assembling large panels, such as cabinet doors or tabletops. They often feature multiple sliding jaws along a longer bar, allowing you to apply pressure across the entire panel surface for even glue distribution.

Corner Clamps

Corner clamps are designed to hold two pieces of wood at a 90-degree angle, making them useful for assembling frames, boxes, and other right-angle joints.

Edge Clamps

Edge clamps, also known as bar edge clamps, are designed to hold workpieces securely along their edges. They are useful for tasks such as edge banding and routing.

These are just a few examples of the various types of bar clamps available. The choice of clamp depends on the specific woodworking task and the size of the project. Different types of bar clamps offer different features and advantages, so it's important to select the right clamp for your needs to achieve the best results.

What are purpose of Bar Clamps?

Bar clamps serve several important purposes in woodworking and various other applications:

Gluing and Assembly

One of the primary purposes of bar clamps is to hold pieces of wood together while glue dries or sets. This ensures a strong and secure bond between the glued surfaces. Bar clamps are used to assemble various woodworking projects, such as cabinets, furniture, and frames, by keeping the pieces in place until the adhesive has fully cured.

Joinery and Alignment

Bar clamps are essential for aligning and holding wood pieces during joinery tasks, such as edge joining, doweling, and biscuit joining. They help maintain precise alignment and prevent movement while creating strong, accurate joints.

Panel and Tabletop Assembly

When creating large panels or tabletops, bar clamps are used to hold multiple boards together, ensuring a flat and even surface. This is crucial for maintaining structural integrity and aesthetic appeal.

Bending and Shaping

Bar clamps can be used to hold wood pieces in specific shapes while steam bending or shaping, helping woodworkers achieve desired curves and contours.

Machining and Sanding

During machining processes like planing, routing, or sanding, bar clamps can secure the workpiece to a workbench or jig, preventing movement and ensuring consistent results.

Holding and Fixturing

Bar clamps are useful for holding components, jigs, and fixtures in place during various stages of a woodworking project. This can include securing templates, workholding devices, and auxiliary fences to ensure accurate and repeatable cuts.

Repairs and Restorations

Bar clamps are valuable for repairing broken or damaged wooden pieces. They can hold pieces together while adhesives or epoxy cure, helping restore the original strength and integrity of the item.

Custom Jigs and Fixtures

Woodworkers often create custom jigs and fixtures for specific tasks. Bar clamps can be integrated into these jigs to provide precise and adjustable clamping pressure, improving the accuracy and repeatability of operations.

Fine Woodworking and Finishing

In fine woodworking, where attention to detail is crucial, bar clamps can be used to hold delicate or intricate pieces together during intricate carving, inlay work, or finishing touches.

Temporary Holding

Bar clamps can serve as temporary holding devices for various project components, allowing woodworkers to check alignments, measurements, and fits before making final adjustments or permanent fastenings.

Metalworking and Other Applications

While primarily used in woodworking, bar clamps can also find applications in other fields such as metalworking, construction, and DIY projects where securing and holding materials is necessary.

Overall, the versatility and adjustability of bar clamps make them an essential tool in woodworking and various other tasks that require precise alignment, secure holding, and even pressure distribution.

Benefits of Bar Clamps

Bar clamps offer several benefits that make them a valuable tool in woodworking and other applications. Some of the key benefits of bar clamps include:

Even Pressure Distribution

Bar clamps provide consistent and even pressure along the length of the workpiece. This helps ensure that glued joints and assembled pieces bond securely and evenly, resulting in strong and reliable connections.

Versatility

Bar clamps are versatile tools that can be used for a wide range of woodworking tasks, from gluing and assembly to joinery, bending, shaping, and more. They are suitable for various project sizes and types, making them an essential addition to any woodworking workshop.

Adjustability

Bar clamps feature adjustable sliding jaws that can be positioned to accommodate different workpiece sizes and shapes. This adjustability allows for precise alignment and customization, making them suitable for diverse woodworking projects.

Long Clamping Reach

Bar clamps come in various lengths, offering the ability to clamp larger workpieces or multiple pieces simultaneously. This makes them useful for tasks such as panel assembly and holding large projects in place.

Parallel Clamping

Many bar clamps, especially parallel jaw clamps, maintain parallel pressure along the entire length of the jaws. This feature prevents misalignment and ensures that workpieces stay flat and properly joined.

Durability

Bar clamps are typically constructed from sturdy materials such as steel or aluminum, which ensures their durability and longevity even with heavy use.

Quick and Easy Operation

Some bar clamps, such as quick-grip and one-handed clamps, are designed for rapid adjustments and quick release. This feature speeds up the clamping process and makes them suitable for tasks that require frequent adjustments.

Accurate Joinery

Bar clamps help achieve precise joinery by holding pieces in place during cutting, shaping, or drilling. This accuracy contributes to the quality and professionalism of woodworking projects.

Custom Jigs and Fixtures

Bar clamps can be integrated into custom jigs and fixtures, allowing woodworkers to create specialized holding and workholding solutions tailored to specific tasks.

Cost-Effectiveness

Bar clamps are available at various price points, making them accessible to woodworkers with different budgets. They provide excellent value for the functionality they offer.

Repair and Restoration

Bar clamps are valuable for restoring and repairing damaged pieces by holding components together while adhesives cure, allowing for effective fixes.

DIY and Home Improvement

Bar clamps are not limited to professional woodworking; they are also useful for DIY projects and home improvement tasks that require secure holding and alignment.

How to choose Bar Clamps?

Choosing the right bar clamps for your woodworking projects involves considering several important factors to ensure you have the appropriate tools for the task at hand. Here are the key considerations when selecting bar clamps:

Type of Projects

Determine the types of projects you frequently work on. Different projects may require specific features, such as parallel clamps for panel assembly, one-handed clamps for quick adjustments, or deep throat clamps for reaching into large workpieces.

Clamping Capacity

Consider the maximum opening width of the clamp, often referred to as the clamping capacity. Choose bar clamps that can accommodate the size of the workpieces you typically work with.

Throat Depth

If you often work with thicker materials or need to reach further into a workpiece, opt for clamps with a deeper throat depth. This will give you more flexibility in clamping different sizes of projects.

Number of Clamps

Evaluate how many clamps you'll need for your projects. Having a variety of sizes and types can be advantageous for different tasks. Consider purchasing clamps in sets to ensure you have a range of options.

Quality and Material

Look for bar clamps made from high-quality materials such as steel or aluminum. Higher-quality clamps are more durable and less likely to flex or warp under pressure.

Parallel Jaws

If precise alignment is crucial, consider parallel jaw clamps. These maintain even pressure and keep workpieces flat during clamping, making them ideal for gluing and assembly tasks.

Quick Adjustment Mechanism

For convenience and efficiency, consider one-handed or quick-grip clamps that allow for rapid adjustments and release.

Bar Length

Choose bar lengths that match the size of your projects. Longer bars can handle larger workpieces, while shorter bars are more suitable for smaller tasks.

Grip and Padding

Look for clamps with non-marring pads on the jaws to protect the surface of your workpieces. A secure grip ensures that the workpieces remain in place during clamping.

Cost and Budget

Consider your budget and prioritize quality over quantity. While cheaper clamps may be appealing, investing in higher-quality clamps can save you money in the long run due to their durability and performance.

User Comfort

Consider the design of the handle or grip. Ergonomically designed handles can provide more comfort during extended clamping sessions.

Reviews and Recommendations

Read reviews and seek recommendations from fellow woodworkers or professionals to get insights into the performance and reliability of specific clamp brands and models.

Brand Reputation

Choose reputable and well-known brands that have a history of producing quality woodworking tools.

Warranty and Customer Support

Check if the clamps come with warranties or guarantees. Good customer support can be valuable if you encounter any issues with your clamps.

Accessories and Compatibility

Some clamps may have additional accessories or attachments available, such as clamp extenders or adaptors, which can enhance their versatility.

By considering these factors and assessing your specific woodworking needs, you can choose bar clamps that will provide you with reliable and effective clamping solutions for your projects. It's a good idea to start with a variety of clamp types and sizes to build a versatile collection over time.

In conclusion

Overall, bar clamps are versatile, reliable, and essential tools that help woodworkers achieve accurate and professional results in a wide range of woodworking projects. Their ability to apply even pressure and hold workpieces securely makes them a fundamental part of any woodworking toolkit.

To buy towing winch shackles, you can buy in store but if you don’t have time, I recommend you to buy in Amazon. That platform offer you with various products and wide range price together promotion. Buy in Amazon, you will easily find your need. To make you easily choose towing winch shackles in Amazon, we selected top best seller towing winch shackles in our website. Read carefully and Enjoy!

I’m David Lee - editor at best2buy.reviews. If you need our support. Kindly comment below. I’m always available to response you.