How to Choose the Electrical Tape

Electrical Tape: Everything You Need To Know

- 1. Electrical Tape: Everything You Need To Know

- 1.1. What Is Electrical Tape?

- 1.2. Types of Electrical Tape

- 1.3. Common Uses of Electrical Tape

- 1.4. Things to Consider When Choosing Electrical Tape

- 1.4.1. Tape Grade

- 1.4.2. Color

- 1.4.3. Tape Stretch

- 1.4.4. Ease of Use

- 1.4.5. Code Compliance

- 1.5. Safety Tips

Electrical tape, a versatile tool, holds a pivotal position in the realms of electrical work, do-it-yourself (DIY) projects, and routine household fixes. Engineered to insulate, shield, and firmly fasten electrical connections, this adhesive tape is an indispensable asset in every electrician's arsenal and a valuable addition for homeowners and hobbyists alike. This comprehensive guide is your compass to delve into the diverse variations of electrical tape, its myriad applications, and essential safety guidelines, all aimed at optimizing the utility of this versatile tool.

What Is Electrical Tape?

Electrical tape, often referred to as "phasing tape," is a type of adhesive tape specifically engineered for insulating wires and materials that conduct electricity. It is typically manufactured with a non-corrosive rubber-based adhesive and a polyvinyl chloride (PVC) backing, which imparts the tape with the capacity to stretch and conform to wires and cables.

Additionally, this insulating tape plays a crucial role in electrical applications as a means of coding. The various colors of electrical tape are used to signify the voltage level and phase of the wire, hence its popular nickname, "phasing tape."

Electrical tape, often referred to as "phasing tape," is a type of adhesive tape specifically engineered for insulating wires and materials that conduct electricity. It is typically manufactured with a non-corrosive rubber-based adhesive and a polyvinyl chloride (PVC) backing, which imparts the tape with the capacity to stretch and conform to wires and cables.

Additionally, this insulating tape plays a crucial role in electrical applications as a means of coding. The various colors of electrical tape are used to signify the voltage level and phase of the wire, hence its popular nickname, "phasing tape."

Types of Electrical Tape

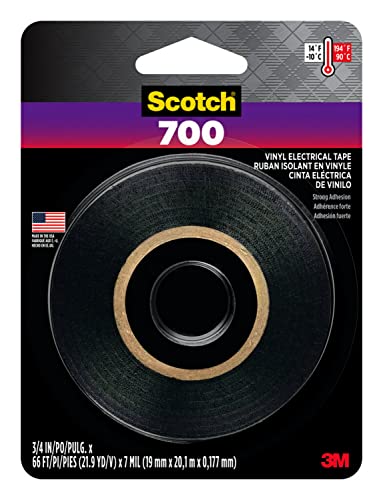

- Vinyl Electrical Tape: The most common type of electrical tape is vinyl electrical tape. It is crafted from a pliable, sturdy vinyl material, which offers exceptional insulation capabilities and stands up well against moisture, acids, alkalis, and UV rays. Vinyl electrical tape is obtainable in an assortment of colors, aiding in the simple identification and color-coding of wires.

- Rubber Electrical Tape: Renowned for its remarkable elasticity and capacity to stretch, rubber electrical tape is ideal for applications demanding a snug, moisture-resistant seal. This type is frequently employed in high-voltage scenarios, including the splicing of power cables.

- Silicone Electrical Tape: Silicone tape is a self-fusing tape that adheres to itself when extended and wrapped around an object. It exhibits exceptional resistance to extreme temperatures, and it is commonly utilized in automotive, marine, and aerospace applications. This tape leaves no adhesive residue behind, rendering it user-friendly.

Common Uses of Electrical Tape

- Insulating Wires: Electrical tape serves as a crucial insulating agent for wires and connections, effectively preventing electrical conductivity, guarding against short circuits, and ensuring the safety of individuals. When applied correctly, it acts as a dependable barrier between conductors.

- Color Coding: Electricians frequently employ a range of distinct colors of electrical tape to designate wires and their respective functions. This system of color coding aids in the diagnosis of issues and maintenance tasks while guaranteeing precise connections during installations.

- Cord and Cable Repairs: Electrical tape is a common choice for rectifying damages to cords, cables, and extension cords. It offers both temporary and potentially permanent solutions for minor repairs, including concealing exposed wires and sealing small tears.

- Temporary Fastening: When a swift and convenient fastening method is required, electrical tape proves useful in securing objects together. It finds frequent application in do-it-yourself (DIY) projects and serves as a temporary means of keeping components in place.

- Emergency Repairs: In emergency scenarios, such as when a pipe is leaking or when there is a need to mend a tear in a tent, electrical tape can be a lifesaver. Its versatility extends beyond electrical uses and can be employed for various non-electrical applications.

Things to Consider When Choosing Electrical Tape

With so much at stake, selecting the right electrical tape is of utmost importance to ensure the job is done correctly on the first attempt. Here are the factors to take into consideration when making your choice:

Tape Grade

The grade of the tape you choose significantly impacts its performance. Aspects like backing construction, thickness, and dielectric strength are all part of the tape grade. Electrical tape backings can be either monomeric or polymeric in construction. Monomeric tapes, made with short-chain plasticizers, are economical and suitable for light-duty, general tasks but tend to degrade over time. In contrast, polymeric electrical tapes, with long-chain plasticizers, offer greater durability, tighter seals, and enhanced corrosion protection for professional applications. Typically, lower-grade tapes are monomeric, while higher-grade tapes are polymeric. Thickness and dielectric strength tend to increase with higher tape grades, so consider this when selecting a tape for your specific application.

Color

While black is the most common color for basic general-purpose electrical tape, tapes are available in various colors. These colors are primarily used for phasing tasks to color-code wires, indicating voltage, phase, and other crucial information for electricians. Choosing the right color of electrical tape for phasing tasks is essential for safety, as the wrong color could lead to inaccurate voltage readings, posing risks for technicians. Ensure you use the appropriate colors for your specific application and familiarize yourself with the color code if needed.

Tape Stretch

The quality of a tape is not only measured by its ability to maintain its hold over time but also by its ability to stretch and return to its original form. Elongation is a key parameter used to describe how much an electrical tape can stretch before breaking. A higher elongation indicates that the tape can stretch further without breaking. Equally important is a tape's ability to revert to its original shape after stretching. Lower-grade tapes, particularly those with monomeric construction, tend to maintain their stretched-out shape rather than returning to form and securely holding the phased or insulated wire. You can easily differentiate between black monomeric and polymeric tapes, as monomeric tapes lighten and appear gray when stretched, while polymeric tapes remain black, signifying a more stable construction. To insulate a wire properly with electrical tape, it must be stretched during application and should naturally return to its original form afterward, ensuring a secure hold that withstands moisture and other elements. For minor, non-critical tasks where lower-quality tape suffices, it's acceptable for the tape to have less elongation. However, for major jobs requiring precision and long-term adherence, always opt for a tape with high stretch that returns to its original form.

Ease of Use

Don't overlook the importance of selecting an electrical tape that is easy to handle. Look for a tape that can be torn by hand and is easy to wrap around wires. It should adhere quickly and unwind smoothly from the roll without twisting or curling during application, preventing frustration during the job.

Code Compliance

Electricians are aware that the tools they use and how they use them are critical for ensuring a job complies with building codes. When choosing electrical tape, carefully examine the label to determine if it meets the requirements outlined by your local building codes. Tapes that are UL Listed or CSA approved have undergone rigorous testing to ensure they meet the performance standards necessary for a job well done.

Safety Tips

- Proper Installation: When employing electrical tape for electrical purposes, it is essential to tightly and evenly wrap it to establish a secure and efficient seal. To guarantee a dependable insulating layer, overlap the tape by half its width.

- Inspect for Damage: Always examine the tape for any indications of wear, damage, or degradation before utilizing it. Compromised tape can jeopardize the insulation and safety of electrical connections.

- Avoid Excessive Stretching: Although certain tapes are designed to be stretchable, excessive stretching can diminish the tape's strength and performance. Adhere to the manufacturer's recommendations for stretching and applying the tape.

- Temperature Considerations: Different tapes come with varying temperature ratings. Ensure that you choose a tape that can endure the temperature conditions in your specific application. For instance, silicone tape is an excellent choice for high-temperature environments.

- Replace When Necessary: Electrical tape is not a permanent solution for all applications. If you are using it as a temporary remedy, be sure to replace it with a more durable, long-term solution whenever feasible.

- Labeling: When utilizing colored tape for identification, establish a key or label to facilitate clear understanding of the color code for anyone working on the electrical system.

In conclusion, electrical tape stands as a versatile and indispensable resource for electricians, DIY enthusiasts, or anyone in need of insulating, safeguarding, or fastening wires and connections. By selecting the appropriate tape and employing proper application methods, you can guarantee the safety and dependability of your electrical projects and maintenance. Make safety your top priority and adhere to recommended practices when handling electrical tape to avoid accidents and promote the durability of your electrical systems.