Depth Gauges: The Ultimate Guide to Choosing The Right One

- 1. Depth Gauges: The Ultimate Guide to Choosing The Right One

- 1.1. What Is A Depth Gauges?

- 1.2. Types of Depth Gauges

- 1.3. Applications of Depth Gauges

- 1.4. Factors To Consider When Choosing A Depth Gauge

- 1.4.1. Depth Gauge Types

- 1.4.2. Measurement Range

- 1.4.3. Resolution and Accuracy

- 1.4.4. Ease of Use

- 1.4.5. Calibration and Maintenance

- 1.4.6. Cost and Budget

- 1.5. The Importance of Depth Gauges

Depth gauges, integral precision tools employed across diverse sectors and applications, serve the purpose of quantifying an object's depth or thickness, or alternatively, the depth of a hole or groove. They are pivotal instruments that uphold precision and exactitude within an extensive spectrum of domains, encompassing manufacturing, construction, engineering, and research. In the subsequent sections, we shall delve into depth gauges, their variations, practical utilities, and their substantial importance in multifarious industries.

What Is A Depth Gauges?

A depth gauge, sometimes referred to as a depth indicator or depth measurement tool, is an apparatus or instrument employed for quantifying the depth or thickness of an object, or a particular dimension within an object. These gauges assume diverse configurations and find extensive utility across various sectors and industries.

Types of Depth Gauges

There are various types of depth gauges available, each tailored for specific applications. Here is an overview of some common varieties:

- Dial Depth Gauges: These depth gauges feature a dial indicator affixed to a base. The indicator uses a probe inserted into a hole or groove to measure depth. The depth measurement is displayed on a dial face, ensuring readability and high accuracy.

- Vernier Depth Gauges: Vernier depth gauges are precision instruments employing a sliding scale for measurement. The primary scale and the vernier scale work in conjunction to provide precise depth readings. These gauges are frequently employed in machining and metrology.

- Digital Depth Gauges: Equipped with electronic components, digital depth gauges offer accurate and easily readable measurements. They typically incorporate an LCD screen displaying depth measurements in millimeters, inches, or other units, making them convenient for swift and precise measurements.

- Micrometer Depth Gauges: Micrometer depth gauges function similarly to standard micrometers but are specifically designed for measuring the depth of small holes and recesses. They offer a high level of accuracy and are used in applications where precision is paramount.

- Depth Micrometers: These specialized micrometers are designed for measuring the depth of holes, slots, or other recesses. They feature a flat base and a spindle with a pointed end, making them well-suited for precise measurements in confined spaces.

- Depth Calipers: Depth calipers share similarities with standard calipers but have extended jaws crafted for measuring the depth of grooves, recesses, and holes. They are versatile and user-friendly in a variety of applications.

Applications of Depth Gauges

Depth gauges serve a wide range of applications across various sectors and industries, encompassing:

- Manufacturing: Within the manufacturing sector, depth gauges prove invaluable for verifying that components and parts are machined with precision to achieve the correct depth and dimensions. This is instrumental in upholding quality and consistency during the production process.

- Construction: Depth gauges are essential tools for construction professionals as they enable the measurement of hole depths drilled for a multitude of purposes, such as securing structures, installing utilities, and ensuring that materials like concrete are poured to the accurate depth.

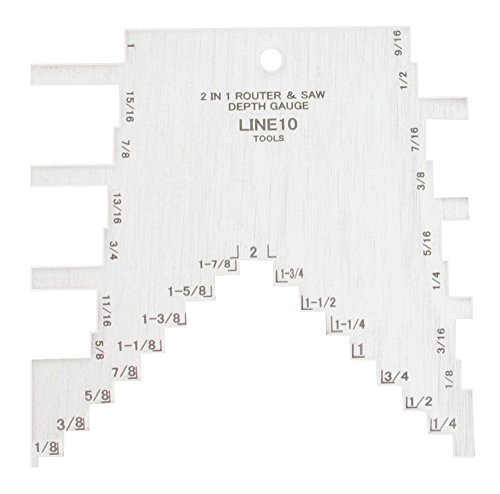

- Woodworking: Woodworkers heavily rely on depth gauges to set the appropriate depth for cuts, drilling holes, and ensuring the precise fitting of joints in carpentry projects.

- Metalworking: Metalworkers utilize depth gauges to gauge the depth of holes, threads, and other features in metal components. Precise measurements are vital for guaranteeing the functionality and safety of metal parts.

- Research and Development: In the realm of research and development, depth gauges find application in meticulously measuring and documenting the depth of features in a variety of materials. This aids in the design and development of new products and processes.

- Quality Control: Depth gauges play a pivotal role in quality control procedures by verifying that products conform to the required specifications and tolerances. They are instrumental in confirming the depth of critical features in manufactured parts.

Factors To Consider When Choosing A Depth Gauge

When it comes to selecting a depth gauge, there are several essential factors to take into account to ensure that you obtain the most suitable tool for your specific needs. In this article, we will delve into the key considerations when making your choice.

Depth Gauge Types

Depth gauges are available in various types, each designed for specific applications. Common types include dial indicators, digital calipers, micrometers, vernier calipers, and laser-based gauges. Your choice of type should primarily hinge on the level of precision required for your task and the environmental conditions in which the gauge will be utilized. For instance, digital gauges provide high precision and user-friendliness, while dial indicators are often more rugged and suitable for industrial environments.

Measurement Range

The measurement range of a depth gauge is of paramount importance as it dictates the maximum and minimum depths that can be accurately measured. Ensure that the depth gauge you choose has a range that aligns with your project's requirements. Overstepping the range or underutilizing it can result in measurement inaccuracies.

Resolution and Accuracy

The resolution and accuracy of the depth gauge are critical factors. Resolution denotes the smallest depth change the gauge can detect, while accuracy indicates how closely the gauge's measurements align with the actual depth. For tasks demanding precision, opt for a gauge with high resolution and accuracy. Digital depth gauges typically excel in accuracy compared to mechanical alternatives.

Ease of Use

Factor in the user-friendliness of the depth gauge. Digital gauges usually offer clear readings and ease of operation. However, also pay attention to factors like ergonomics and the legibility of the measurement scale. A user-friendly depth gauge can enhance productivity and minimize the likelihood of errors.

Calibration and Maintenance

Like all measurement instruments, depth gauges require periodic calibration and maintenance to ensure accuracy. When selecting a depth gauge, consider the simplicity of calibration and the availability of calibration services. Some digital models are equipped with built-in calibration features for user convenience.

Cost and Budget

Undoubtedly, your budget is a crucial factor. High-precision, feature-rich depth gauges may come at a higher price. It's worth noting that, at times, investing in a more expensive and accurate gauge can ultimately save money by reducing errors and the need for rework.

The Importance of Depth Gauges

The significance of depth gauges cannot be overstated in precision-critical industries. Here are several compelling reasons why depth gauges are absolutely indispensable:

- Precision: Depth gauges provide a level of precision that is paramount in industries where even minor deviations from specified measurements can result in defects or failures.

- Consistency: These tools play a pivotal role in maintaining consistency throughout manufacturing processes. They ensure that components are produced with the same depth and dimensions on every occasion.

- Quality Assurance: Depth gauges are of paramount importance in quality control procedures. They enable the detection and correction of any deviations from desired specifications, thus guaranteeing product quality.

- Safety: In construction and other safety-critical applications, accurate depth measurements are vital to ensure the secure and safe installation of structures and components.

- Efficiency: Depth gauges streamline and expedite the measurement process, ultimately saving time and reducing the likelihood of errors and the need for rework.

In conclusion, depth gauges play a crucial and versatile role in a wide range of industries, including manufacturing, construction, research, and development. These tools come in various forms and are essential for upholding precision, quality, and safety within their specific applications. As technology progresses, the precision and convenience of depth gauges are set to enhance, further enhancing the efficiency and efficacy across diverse sectors.