How to Choose the Industrial Lubricants

Hi my readers! It’s Samantha Kim from best2buy.reviews. Today, I'm excited to share some tips for choosing Industrial Lubricants. It will help you easily to decide! Let’s check it now!

- 1. What are Industrial Lubricants?

- 2. Characteristics and functions of industrial lubricants

- 2.1. Friction Reduction:

- 2.2. Heat Dissipation:

- 2.3. Wear Protection:

- 2.4. Corrosion Prevention:

- 2.5. Sealant Properties:

- 2.6. Viscosity Control:

- 2.7. Temperature Stability:

- 2.8. Compatibility:

- 3. Types of Industrial Lubricants

- 3.1. Mineral Oil Lubricants:

- 3.2. Synthetic Lubricants:

- 3.3. Greases:

- 3.4. Biodegradable Lubricants:

- 3.5. High-Temperature Lubricants:

- 3.6. Low-Temperature Lubricants:

- 3.7. Food-Grade Lubricants:

- 3.8. Hydraulic Fluids:

- 3.9. Gear Lubricants:

- 3.10. Compressor Lubricants:

- 3.11. Turbine Lubricants:

- 3.12. Metalworking Fluids:

- 4. Benefits of Industrial Lubricants

- 4.1. Friction Reduction:

- 4.2. Wear Protection:

- 4.3. Heat Dissipation:

- 4.4. Corrosion Prevention:

- 4.5. Sealant Properties:

- 4.6. Energy Efficiency:

- 4.7. Extended Equipment Life:

- 4.8. Improved Performance:

- 4.9. Increased Productivity:

- 4.10. Temperature Stability:

- 4.11. Reduced Maintenance Costs:

- 4.12. Environmental Considerations:

- 4.13. Specialized Applications:

- 4.14. Compatibility:

- 4.15. Contaminant Control:

- 5. How to choose Industrial Lubricants?

- 5.1. Application Requirements:

- 5.2. Operating Conditions:

- 5.3. Equipment Specifications:

- 5.4. Load and Speed:

- 5.5. Base Oil Type:

- 5.6. Additives:

- 5.7. Viscosity:

- 5.8. Environmental Considerations:

- 5.9. Compatibility:

- 5.10. Industry Standards and Regulations:

- 5.11. Manufacturer Recommendations:

- 5.12. Analysis and Testing:

- 5.13. Cost Considerations:

- 5.14. Supplier Reputation:

- 5.15. Review Safety Data Sheets (SDS):

- 6. In conclusion

What are Industrial Lubricants?

Industrial lubricants are specialized substances used to reduce friction and wear between moving parts in machinery and equipment within industrial settings. These lubricants play a crucial role in maintaining the efficiency, performance, and lifespan of various mechanical components by minimizing friction, dissipating heat, and preventing corrosion.

Characteristics and functions of industrial lubricants

Key characteristics and functions of industrial lubricants include:

Friction Reduction:

- Lubricants create a thin film between moving surfaces, reducing friction and minimizing wear and tear on machine components.

Heat Dissipation:

- By reducing friction, industrial lubricants help dissipate heat generated during the operation of machinery, preventing overheating and potential damage.

Wear Protection:

- Lubricants form a protective barrier on surfaces, preventing direct contact between metal parts and minimizing wear and tear.

Corrosion Prevention:

- Industrial lubricants often contain additives that protect metal surfaces from corrosion, extending the life of machinery and equipment.

Sealant Properties:

- Some lubricants act as effective sealants, preventing the entry of contaminants and foreign particles into the system.

Viscosity Control:

- Lubricants come in various viscosities, and selecting the appropriate viscosity is crucial for optimal performance. Viscosity affects the lubricant's ability to flow and maintain a protective film between moving parts.

Temperature Stability:

- Industrial lubricants must remain stable at different temperatures and operating conditions to ensure consistent performance.

Compatibility:

- Lubricants need to be compatible with the materials used in the machinery and equipment to avoid adverse reactions that could lead to damage.

Types of Industrial Lubricants

The primary types of industrial lubricants include:

Mineral Oil Lubricants:

- Derived from crude oil.

- Commonly used for general-purpose applications.

- Cost-effective and widely available.

- Suitable for moderate operating conditions.

Synthetic Lubricants:

- Chemically engineered for specific performance characteristics.

- Can operate effectively under extreme temperatures and harsh conditions.

- Provide enhanced resistance to oxidation and thermal breakdown.

- Common synthetic lubricants include polyalphaolefin (PAO), esters, and polyalkylene glycols.

Greases:

- Semisolid lubricants consisting of a base oil and a thickening agent (usually a soap).

- Adhere well to surfaces, providing prolonged lubrication.

- Ideal for applications where oil may be impractical or prone to leakage.

- Common types include lithium, calcium, and aluminum complex greases.

Biodegradable Lubricants:

- Environmentally friendly lubricants designed to minimize ecological impact.

- Typically derived from renewable resources like vegetable oils.

- Used in applications where spills could have environmental consequences.

High-Temperature Lubricants:

- Engineered to withstand elevated temperatures.

- Suitable for applications such as industrial ovens, kilns, and high-temperature machinery.

Low-Temperature Lubricants:

- Formulated to remain fluid and effective at low temperatures.

- Commonly used in refrigeration systems, cold storage, and outdoor equipment.

Food-Grade Lubricants:

- Comply with strict regulations for use in food and beverage processing equipment.

- Designed to ensure safety in case of incidental contact with food products.

- Typically white mineral oils or synthetic fluids.

Hydraulic Fluids:

- Specifically formulated for hydraulic systems.

- Transmit power, lubricate moving parts, and dissipate heat in hydraulic equipment.

Gear Lubricants:

- Formulated for use in gearboxes and transmissions.

- Provide excellent anti-wear and extreme pressure properties.

Compressor Lubricants:

- Used in air compressors to reduce friction and heat.

- Ensure proper sealing and lubrication of compressor components.

Turbine Lubricants:

- Designed for use in turbines, both steam and gas.

- Provide resistance to oxidation and thermal stability.

Metalworking Fluids:

- Aid in metal cutting, grinding, and forming processes.

- Help cool, lubricate, and remove metal chips during machining operations.

Benefits of Industrial Lubricants

Friction Reduction:

- Lubricants create a protective film between moving parts, minimizing friction and reducing wear and tear on components.

Wear Protection:

- Lubricants form a barrier on surfaces, preventing direct metal-to-metal contact and minimizing wear, which extends the life of machinery.

Heat Dissipation:

- By reducing friction, lubricants help dissipate heat generated during operation, preventing overheating and potential damage to components.

Corrosion Prevention:

- Many industrial lubricants contain additives that protect metal surfaces from corrosion, ensuring equipment longevity and reliability.

Sealant Properties:

- Some lubricants act as effective sealants, preventing the entry of contaminants and maintaining a clean operating environment.

Energy Efficiency:

- Proper lubrication reduces energy consumption by minimizing friction, which can lead to improved overall system efficiency.

Extended Equipment Life:

- Regular lubrication and the use of appropriate industrial lubricants contribute to the longevity of machinery and equipment, reducing the frequency of repairs and replacements.

Improved Performance:

- Lubricants help maintain optimal performance by ensuring that components move smoothly, preventing issues such as sticking or jamming.

Increased Productivity:

- Reliable and well-lubricated machinery is less prone to breakdowns, resulting in increased productivity and reduced downtime.

Temperature Stability:

- Industrial lubricants are designed to maintain stability across a range of temperatures, ensuring consistent performance under various operating conditions.

Reduced Maintenance Costs:

- Proper lubrication minimizes wear and the need for frequent maintenance, leading to cost savings over the lifespan of machinery.

Environmental Considerations:

- Some industrial lubricants are environmentally friendly, meeting regulatory requirements and reducing the environmental impact in case of leaks or spills.

Specialized Applications:

- Different types of industrial lubricants are formulated for specific applications, ensuring that machinery operates optimally in diverse industrial settings.

Compatibility:

- Lubricants are formulated to be compatible with specific materials and components, preventing adverse reactions and ensuring consistent performance.

Contaminant Control:

- Lubricants help trap and suspend contaminants, preventing them from causing damage to sensitive components.

How to choose Industrial Lubricants?

Key factors to consider when selecting industrial lubricants:

Application Requirements:

- Identify the specific application and function of the lubricant (e.g., general machinery, gears, hydraulics, compressors) to choose a product with the appropriate properties.

Operating Conditions:

- Consider the operating temperature, pressure, and environmental conditions (e.g., high/low temperatures, humidity) to select a lubricant that can perform effectively in those conditions.

Equipment Specifications:

- Refer to the manufacturer's recommendations and specifications for the machinery or equipment to determine the type and grade of lubricant recommended.

Load and Speed:

- Evaluate the load-bearing capacity and speed requirements of the machinery to choose a lubricant with the right viscosity and extreme pressure (EP) properties.

Base Oil Type:

- Select a base oil type (mineral, synthetic, or vegetable-based) based on the application requirements and the desired performance characteristics of the lubricant.

Additives:

- Consider the additives present in the lubricant, such as anti-wear, anti-oxidants, anti-corrosion, and anti-foaming agents. Choose additives that address specific challenges in your application.

Viscosity:

- Choose a lubricant with the correct viscosity for the operating temperature range. Viscosity requirements may change with temperature variations, and it's essential to ensure proper flow and lubrication.

Environmental Considerations:

- Consider the environmental impact and regulatory requirements. Some applications may require biodegradable or environmentally friendly lubricants.

Compatibility:

- Ensure that the lubricant is compatible with the materials used in the machinery, including seals and gaskets, to prevent adverse reactions.

Industry Standards and Regulations:

- Be aware of industry standards and regulations that may dictate specific requirements for lubricants in certain applications, such as food-grade lubricants or those used in critical machinery.

Manufacturer Recommendations:

- Follow the recommendations and guidelines provided by the lubricant manufacturer. They often have valuable information on product compatibility and performance.

Analysis and Testing:

- Perform oil analysis and testing to monitor the condition of the lubricant and identify potential issues. This helps in determining the appropriate maintenance intervals.

Cost Considerations:

- While cost is a factor, it's important to balance it with the long-term benefits and performance of the lubricant. Cheaper options may lead to increased maintenance costs or equipment failures.

Supplier Reputation:

- Choose a reputable supplier or manufacturer with a track record of providing high-quality lubricants and excellent customer support.

Review Safety Data Sheets (SDS):

- Familiarize yourself with the safety data sheets for the lubricants you are considering to understand potential hazards and safe handling practices.

By carefully considering these factors, you can select industrial lubricants that best match the requirements of your equipment and application, ultimately promoting efficient and reliable machinery operation. Regular monitoring and adherence to recommended maintenance practices further contribute to the effectiveness of the chosen lubricants.

In conclusion

Industrial lubricants are essential for the smooth and efficient operation of machinery, contributing to increased productivity, reduced maintenance costs, and prolonged equipment life.

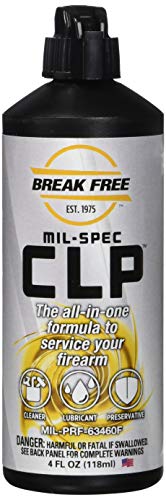

To buy Industrial lubricants, you can buy in store but if you don’t have time, I recommend you to buy in Amazon. That platform offer you with various products and wide range price together promotion. Buy in Amazon, you will easily find your need. To make you easily choose Industrial lubricants in Amazon, we selected top bestseller products in our website. Read carefully and Enjoy!

I’m very happy to response your question. If you need our support, don’t hesitate, kindly comment below. I’m always available to response you. Should read carefully before paying anything.

![WD-40 SMART STRAW Multi-Use Spray - 14.4 OZ [2-Pack]](https://m.media-amazon.com/images/I/51zKbE6lzrL._SL500_.jpg)