- 1. What is Angle Gauges?

- 2. Types of angle gauges

- 2.1. Protractor

- 2.2. Bevel Gauge

- 2.3. Combination Square

- 2.4. Clinometer

- 2.5. Angle Blocks

- 3. Application of Angle Gauges

- 3.1. Woodworking

- 3.2. Metalworking

- 3.3. Construction

- 3.4. Engineering

- 3.5. Surveying

- 3.6. Machine Setup

- 3.7. Automotive Industry

- 3.8. Welding and Fabrication

- 3.9. Art and Design

- 4. Benefits of Angle Gauges

- 4.1. Precision

- 4.2. Time and Cost Savings

- 4.3. Consistency

- 4.4. Ease of Use

- 4.5. Versatility

- 4.6. Improved Safety

- 4.7. Quality Assurance

- 4.8. Design and Layout

- 4.9. Diagnostic Tool

- 4.10. Educational Tool

- 5. How to choose Angle Gauges?

- 6. Type of Angle Gauge

- 6.1. Measurement Range

- 6.2. Precision and Accuracy

- 6.3. Material and Build Quality

- 6.4. Ease of Use

- 6.5. Locking Mechanism

- 6.6. Digital Features (if applicable)

- 6.7. Calibration

- 6.8. Portability

- 6.9. Budget

- 6.10. Reviews and Recommendations

- 6.11. Warranty and Customer Support

- 7. In conclusion

What is Angle Gauges?

Angle gauges, also known as angle measuring tools or angle finders, are instruments used to measure angles in various applications. These tools are commonly found in industries such as construction, engineering, woodworking, metalworking, and other fields where accurate angle measurements are essential.

Types of angle gauges

There are different types of angle gauges, each designed for specific tasks:

Protractor

A basic angle measuring tool used to measure angles between 0 and 180 degrees. Protractors are commonly made of plastic, metal, or transparent material and feature a semicircular shape with degree markings along the arc.

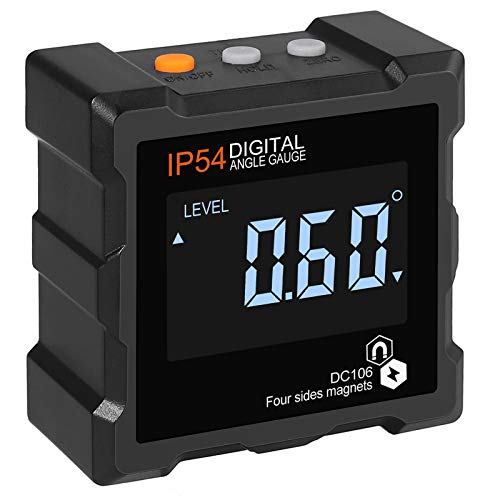

Digital Angle Gauge

A more advanced version of a protractor that provides digital readings of angles. Digital angle gauges often have an LCD display to show the angle measurement with high precision.

Bevel Gauge

A tool used to measure and transfer angles. Bevel gauges typically consist of a handle and a blade with a protractor scale that can be locked in place at a desired angle.

Combination Square

Although primarily used for measuring and marking 90-degree angles, combination squares often have an integrated protractor, allowing them to measure other angles as well.

Clinometer

A specialized angle gauge used to measure the angle of elevation or inclination with respect to the horizontal plane. These are commonly used in surveying and forestry to measure slopes, gradients, or the height of tall objects.

Angle Blocks

Precision metal blocks with accurately machined angles used for checking or setting up other tools or machines to specific angles.

Angle gauges are crucial in tasks such as determining the proper angle for cutting materials, aligning objects, setting up machinery, and ensuring accuracy in various construction and fabrication processes. They come in various sizes, designs, and measurement units (degrees, radians, etc.) to cater to different needs and preferences.

Application of Angle Gauges

Angle gauges have a wide range of applications across various industries and tasks. Some of the common applications of angle gauges include:

Woodworking

In carpentry and woodworking, angle gauges are used to measure and mark angles for cutting and joining wood pieces accurately. This is essential for creating precise joints, bevels, and miter cuts in furniture, cabinets, and other wooden structures.

Metalworking

In metal fabrication and machining, angle gauges help ensure accurate cuts, drilling, and welding. They are used to measure angles for beveling edges, setting up tools, and aligning workpieces in milling, lathe, and other metalworking operations.

Construction

In construction projects, angle gauges are used to measure angles for roof slopes, wall corners, and other critical angles that require precision. They are essential in ensuring that the construction is aligned correctly and built to the required specifications.

Engineering

In engineering tasks, angle gauges play a vital role in designing and manufacturing mechanical components, ensuring proper alignment and fitment. They are used in various engineering disciplines, including civil engineering, mechanical engineering, and aerospace engineering.

Surveying

In land surveying, geodetic surveying, and topographic mapping, clinometers and other angle gauges are used to measure the angles of elevation and inclination to determine slope, height, and distance. This information is crucial for creating accurate maps and models of the terrain.

Machine Setup

Angle gauges, such as bevel gauges and angle blocks, are used in setting up machines and tools at specific angles. This ensures precision in machining operations and the accurate production of parts and components.

Automotive Industry

In the automotive sector, angle gauges are used for wheel alignment, ensuring that the wheels are properly aligned to maintain vehicle stability, tire wear, and fuel efficiency.

Welding and Fabrication

Angle gauges help welders achieve accurate joint angles for strong and reliable welds. They are used to set up the correct bevel angles for various welding processes, such as butt welds, fillet welds, and groove welds.

Art and Design

Artists and designers may use angle gauges to create accurate geometric shapes, architectural drawings, and perspective drawings.

Benefits of Angle Gauges

Angle gauges offer several benefits and advantages in various industries and tasks. Some of the key benefits of using angle gauges include:

Precision

Angle gauges provide accurate measurements of angles, ensuring precise cuts, alignments, and setups. This level of precision is essential in industries like woodworking, metalworking, and engineering, where even a slight deviation from the desired angle can lead to errors and costly rework

Time and Cost Savings

By providing accurate angle measurements, angle gauges help reduce the need for trial and error, thereby saving time and material costs. With precise measurements, tasks can be completed more efficiently and with fewer mistakes.

Consistency

Angle gauges help achieve consistent results, making it easier to replicate angles in multiple pieces or throughout a project. This is especially important in manufacturing, where consistency is critical for quality control and mass production.

Ease of Use

Most angle gauges are user-friendly and straightforward to use, requiring minimal training or expertise. This accessibility makes them valuable tools for both professionals and hobbyists.

Versatility

Angle gauges come in various designs and types, catering to different needs and applications. From simple protractors for basic measurements to digital angle gauges for high-precision tasks, there is a wide range of options available to suit various requirements.

Improved Safety

Accurate angle measurements contribute to safer working conditions. In tasks such as construction, ensuring precise angles can help prevent structural failures and hazards that may result from improper alignments.

Quality Assurance

In manufacturing and fabrication, angle gauges play a crucial role in quality assurance. They help verify that the angles of components and parts meet the required specifications and tolerances

Design and Layout

Angle gauges are essential in the design and layout phase of projects. Architects, engineers, and designers use them to plan and visualize angles in structures, ensuring that the final product meets the desired specifications.

Diagnostic Tool

Angle gauges can be used as diagnostic tools to identify alignment issues in machines, vehicles, and other mechanical systems. By measuring and comparing angles, technicians can pinpoint misalignments and make necessary adjustments for optimal performance.

Educational Tool

Angle gauges are valuable educational tools in schools and vocational training centers. They help students understand geometric principles, trigonometry, and spatial concepts, fostering a deeper understanding of mathematics and engineering.

Overall, angle gauges are indispensable tools that enhance accuracy, efficiency, and safety in various applications. Whether in professional settings or DIY projects, these tools contribute to better results and a smoother workflow.

How to choose Angle Gauges?

Choosing the right angle gauge depends on the specific requirements of your tasks and the level of precision you need. Here are some factors to consider when selecting an angle gauge:

Type of Angle Gauge

Determine the type of angle gauge that best suits your needs. Common types include protractors, digital angle gauges, bevel gauges, combination squares, clinometers, and angle blocks. Each type has its unique features and applications.

Measurement Range

Consider the range of angles the gauge can measure. Some angle gauges are limited to measuring small angles, while others can handle larger angles. Choose one that covers the range of angles you are likely to encounter in your tasks.

Precision and Accuracy

For tasks that require high precision, opt for an angle gauge that offers accurate readings. Digital angle gauges typically provide more precise measurements than traditional protractors.

Material and Build Quality

Look for angle gauges made from durable and reliable materials. Stainless steel and aluminum are common choices as they are robust and resistant to corrosion.

Ease of Use

Consider the ease of use and readability of the angle gauge. Clear and legible markings are crucial, especially in low-light conditions or when working in tight spaces.

Locking Mechanism

If you need to transfer or maintain a specific angle, check if the angle gauge has a locking mechanism. This feature helps keep the gauge in place at the desired angle.

Digital Features (if applicable)

If you are considering a digital angle gauge, look for additional features such as hold function, zero setting, and unit conversion (degrees, radians, etc.).

Calibration

Ensure that the angle gauge is calibrated and provides accurate readings out of the box. Some gauges may require periodic calibration to maintain accuracy.

Portability

If you need to carry the angle gauge to different job sites, consider its size and weight. Portable and compact angle gauges are ideal for on-the-go use.

Budget

Set a budget for your angle gauge purchase and find a balance between features and price that meets your needs

Reviews and Recommendations

Before making a final decision, read reviews and seek recommendations from professionals or hobbyists who have used the angle gauge you are interested in. Their experiences can provide valuable insights.

Warranty and Customer Support

Check for warranties and customer support options in case you encounter any issues with the angle gauge.

By considering these factors, you can choose the most suitable angle gauge that will help you accomplish your tasks with accuracy and efficiency.

In conclusion

Overall, angle gauges are indispensable tools that contribute to precision, accuracy, and efficiency in a wide range of applications. They help professionals and hobbyists alike achieve the desired results in their respective fields.

If you are finding where to buy angle gauges, you can go to Amazon. But in Amazon has many products, and you will meet a trouble to choose the best product. Don’t worry! We help you. We have top featured products which highly appriciate. That wonderfull suggession for you. Try and Buy it now!

I’m Jane Smith, editor at best2buy.reviews. If you have any questions, please feel free to let me know. I’m always availabe to respone any your questions.